On this page are presented some projects made by InventCAD. In carrying out our projects, in addition to the components purchased from the collaborating companies, we use parts produced by us through 3D and CNC milling.

Automatic deburring of parts with KUKA robotic arm

Automation of the automatic deburring operation of the mould scraps after casting of semi-finished parts from which valves for the turbine of thermal engines are produced. The system uses a KUKA robot that performs the deburring/grinding operation of the casting scrap. The system allows measuring the result of the operation and sorting the parts according to the result, evacuating the empty moulds for the parts. The OK parts are placed on an accumulation conveyor which transports them to a stung. A Pick&Place module automatically feeds the CNC lathe with the deburred parts.

automatic grinding operation with KUKA robotic armPublished by InventCAD on Saturday, June 23, 2018

Automatic feeding of a CNC lathe by a Pick&Place system made with SMC components

Pick & PlacePublished by InventCAD on Friday, June 22, 2018

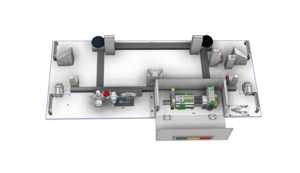

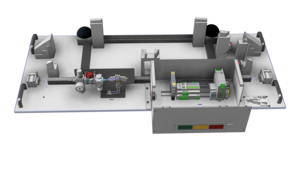

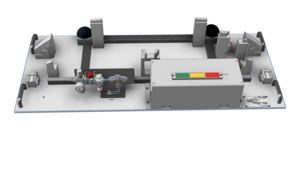

Accumulation tape

Allows parts to accumulate between operations that have different durations. The system also allows the parts to be moved to be picked up as needed by a robotic arm or a Pick&Place system.

Storage bandPublished by InventCAD on Friday, June 22, 2018

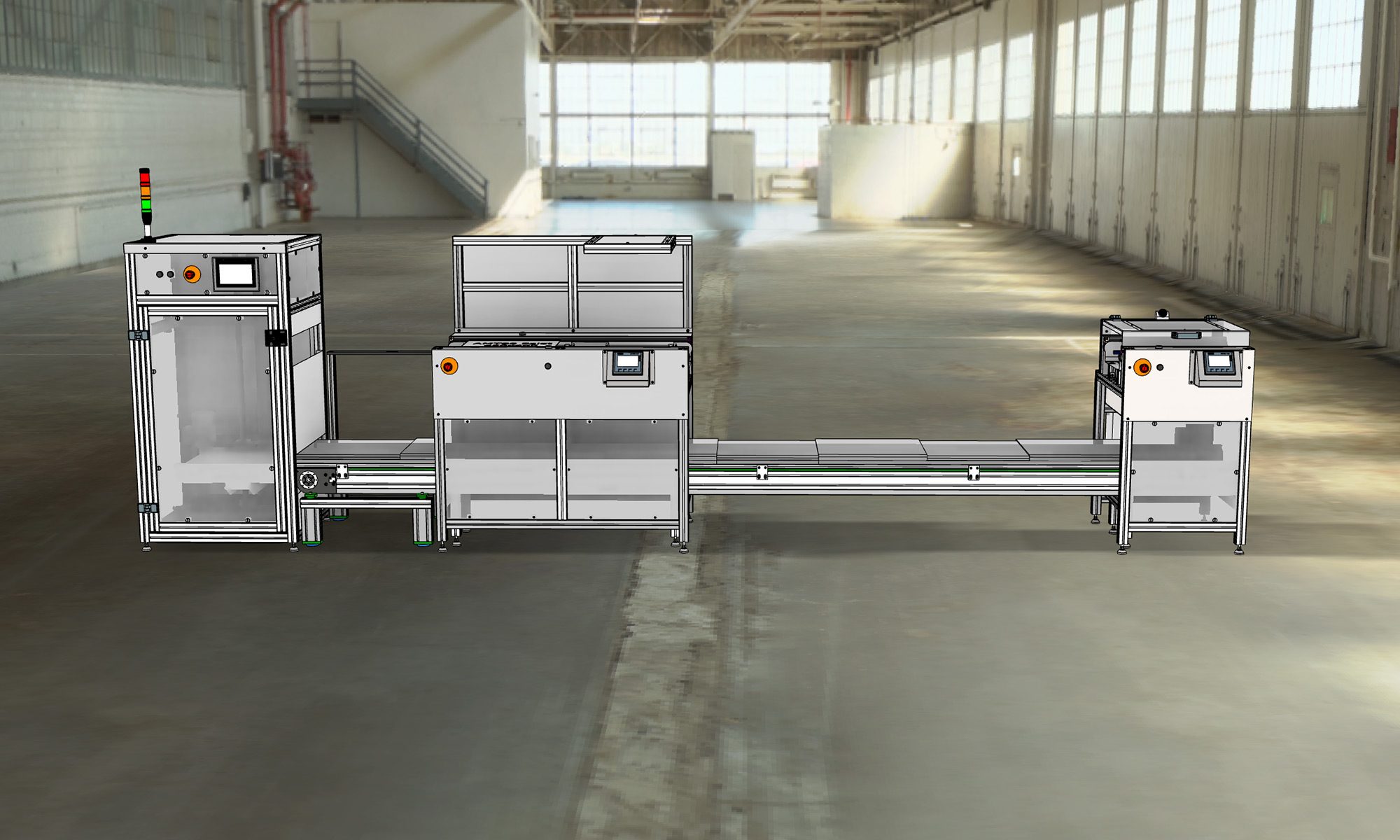

Carrier transport between operations

transfer parts between operationsPublished by InventCAD on Friday, June 22, 2018

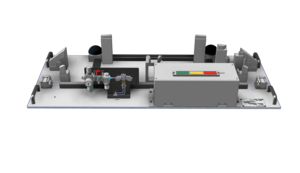

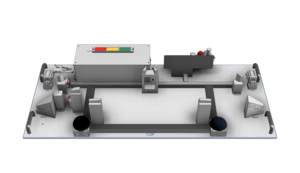

Automatic parts blowing system

Automatic parts blowing systemAutomatic part blowing system

Posted by InventCAD on Sunday, July 28, 2019

Tape sanding machine

Conveior ESD + Lifter

Mounting devices

Mounting devices and checking after mounting.

Simulation of operation during CAD designs

Simulation of officials still in the CAD design phase allows analysis and selection of final versions of the project. In the clips below we predict a few situations where this approach has been used.

Simulation variant 1

Simulation Variant 2

Automatic polishing simulation with KUKA robot

Equipment door opening system

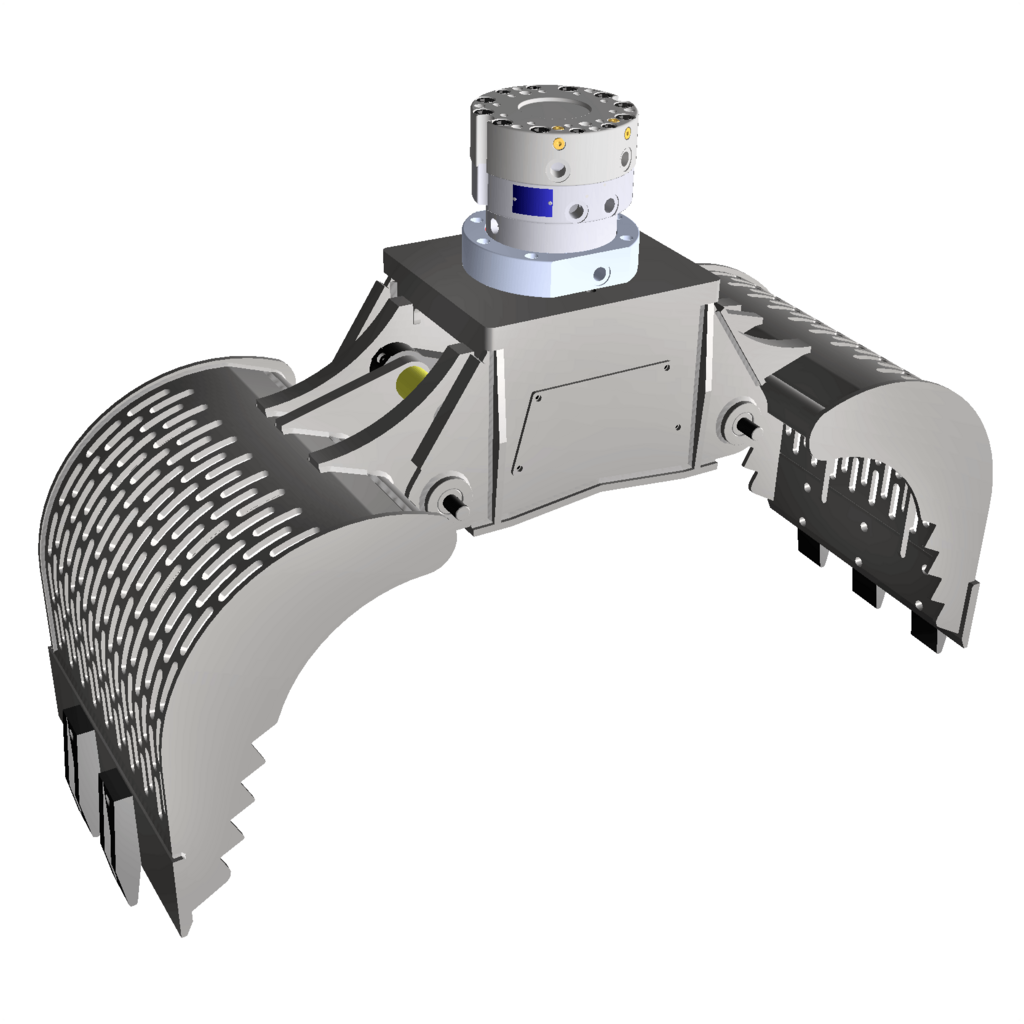

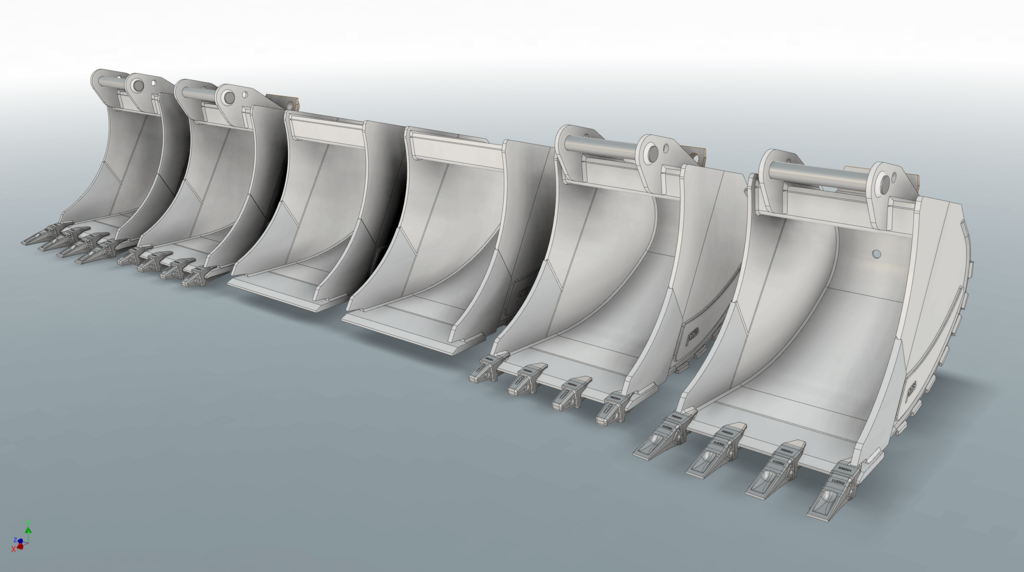

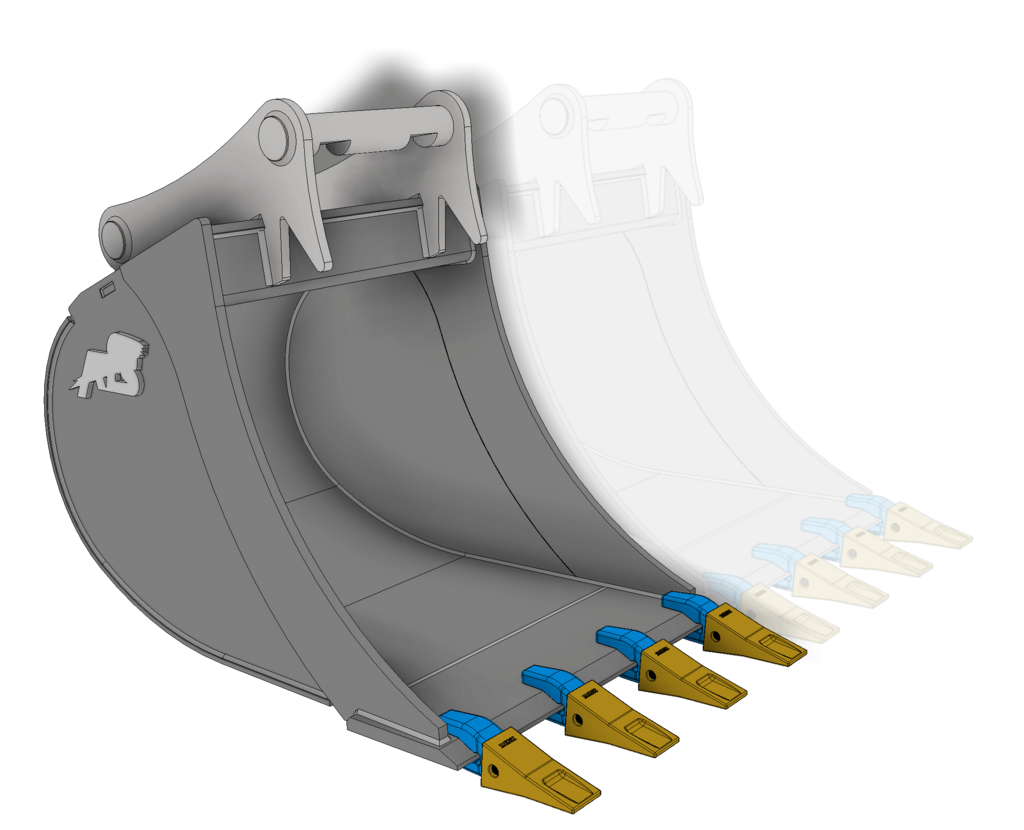

Excavator buckets

Design of excavator buckets and various accessories for construction machinery.