We offer 3D printing services according to the customer's model or models made by us at the customer's request.

Currently we can make 3D printed model using the following materials:

ABS

ABS is a very powerful and versatile material with high thermal resistance. It is suitable for indoor and outdoor use. ABS is a thermoplastic polymer; which means that, like the PLA, it can be melted and crystallized several times without degrading too much. ABS, however, melts at a temperature higher than the PLA. The higher melting temperature gives the high thermal resistance to ABS; models will not show signs of deformation up to 98 ° C.

PLA

PLA is the most commonly used filament. It is biodegradable, easy to print and very powerful. The perfect choice for printing large objects due to its low thermal expansion (little to deformation) and for printing small parts due to low melting temperature.

PLA materials are available in a wide range of colors, some even have special features, such as the ability to shine in the dark.

PET/PETG

PETG is a very hard material with good thermal resistance. It is a universal material, but it is especially suitable for mechanical parts and for indoor and outdoor use. PETG has almost no deformation, so printing large objects is not a problem.

PETG is one of our favorite 3D printing materials. It's almost as easy to print as PLA, but it can offer many mechanical properties that PLA prints can't achieve. G in petg acronym means Glycol, which is added during process manufacturing. The glycol changes the PET properties so that it is easier to print, less fragile and clearer when printing with semi-transparent variations. PETG has a low thermal expansion, so even when printing large objects and without an enclosure, it rarely gets out of bed and twists. In addition, PETG is ductile. It has a degree of flexibility that can prevent live parts from breaking.

FLEX

Flex is a very powerful and flexible material. There are many cases of use when hard plastic is not the best option. Whether you need a phone cover, an action room case, or wheels for your car. RC, flexibility is the way to go.

Flex has a very good abrasion resistance, stays flexible in cold environments and is resistant to multiple solvents. It doesn't shrink too much when it cools down, so you can be pretty accurate with measurements and patterns that require a perfect fit.

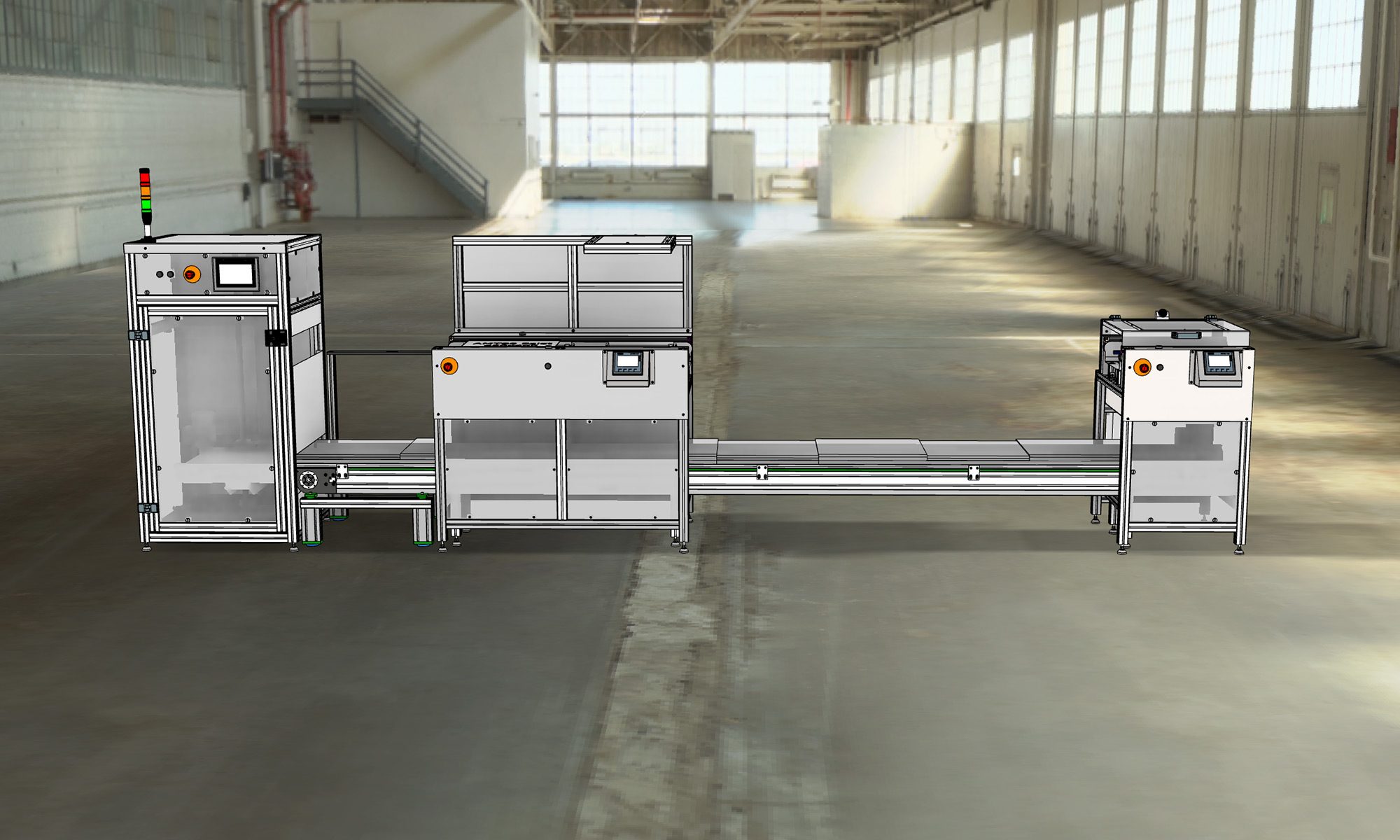

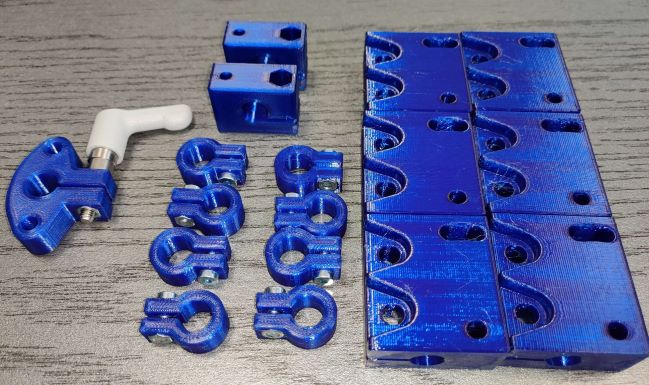

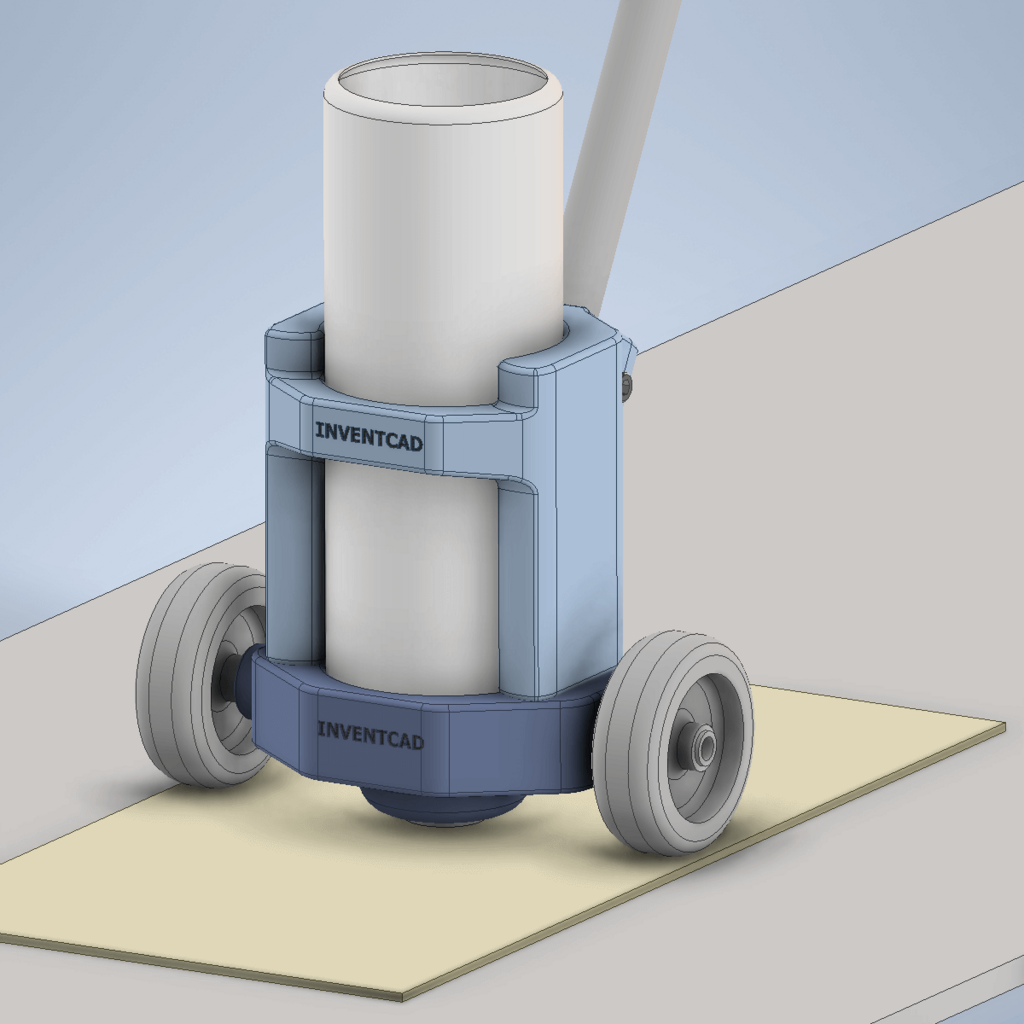

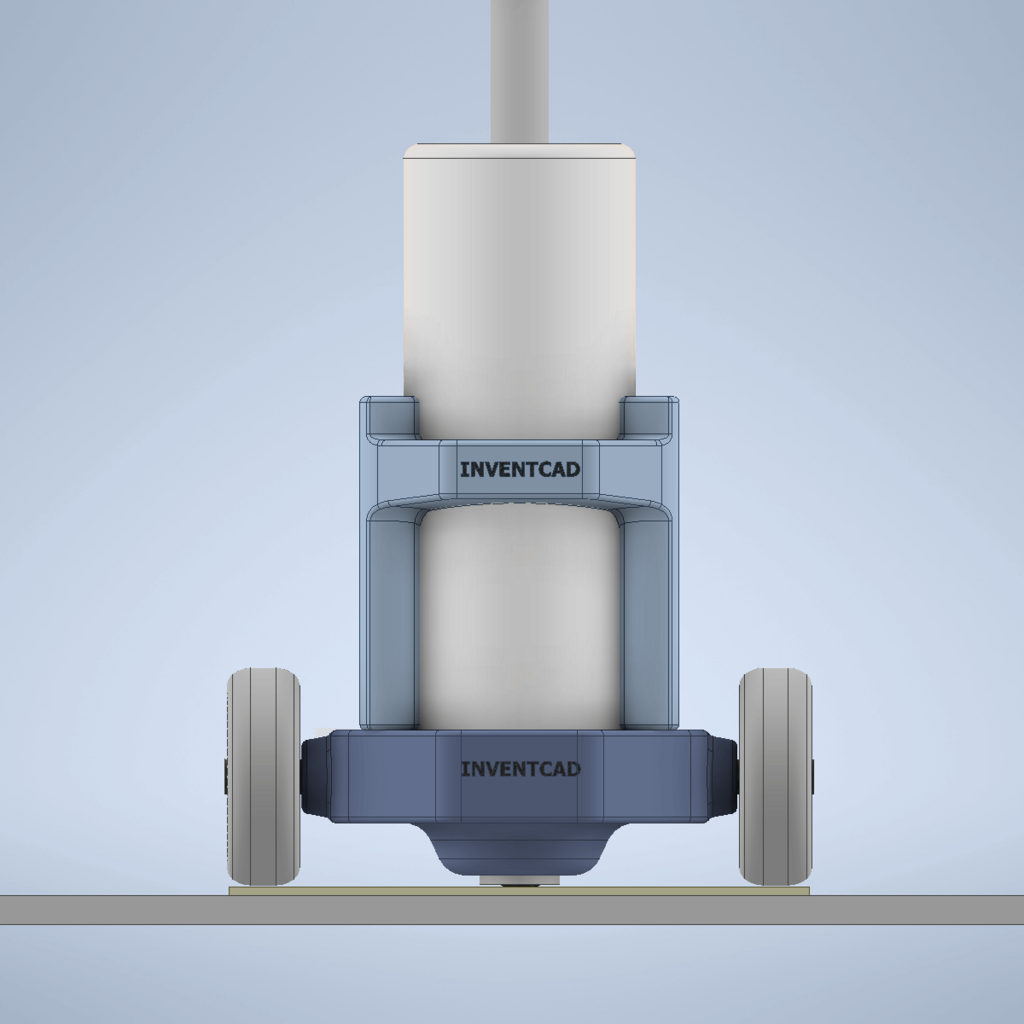

Examples of projects where we used 3D printed parts

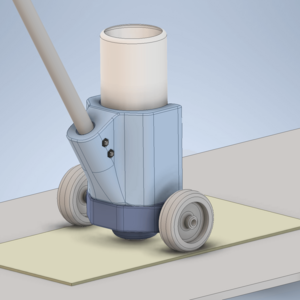

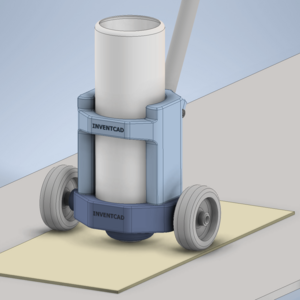

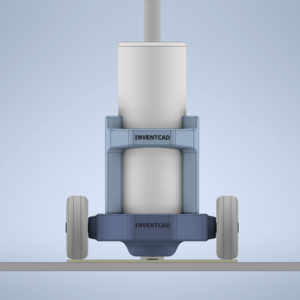

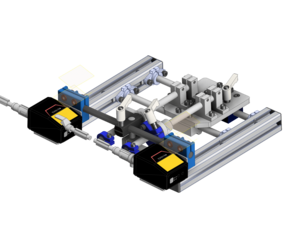

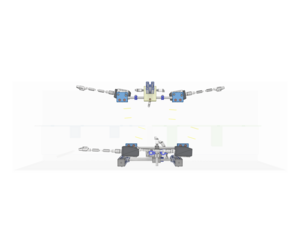

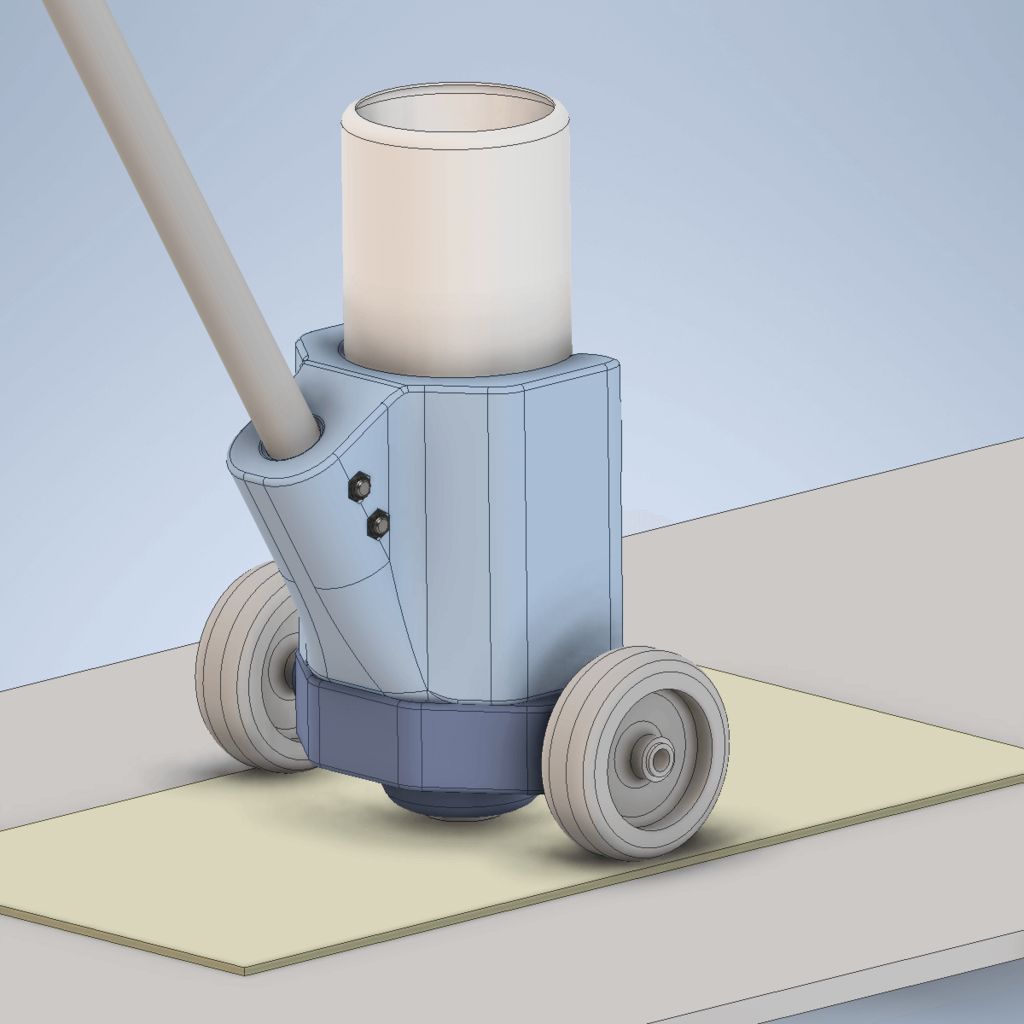

Glue application trolley

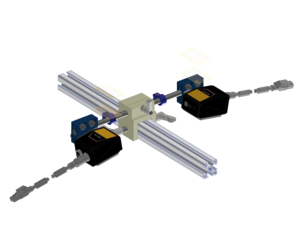

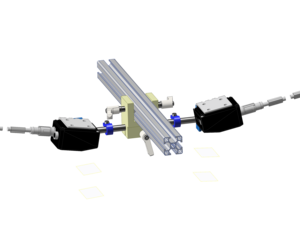

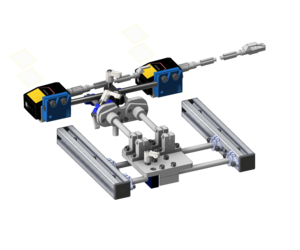

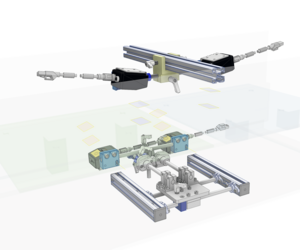

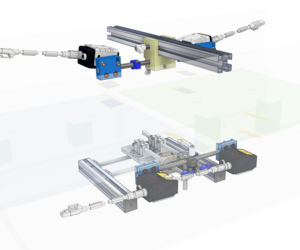

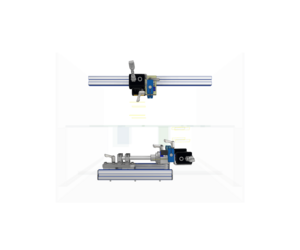

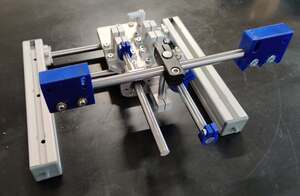

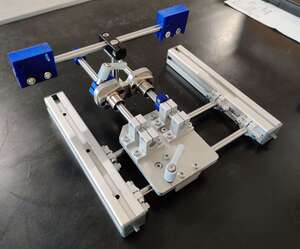

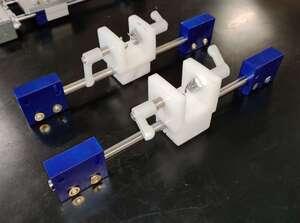

X, Y, Z Sensor Adjustment System – Allows manual adjustment of the position of keyENCE sensors in 3 directions.