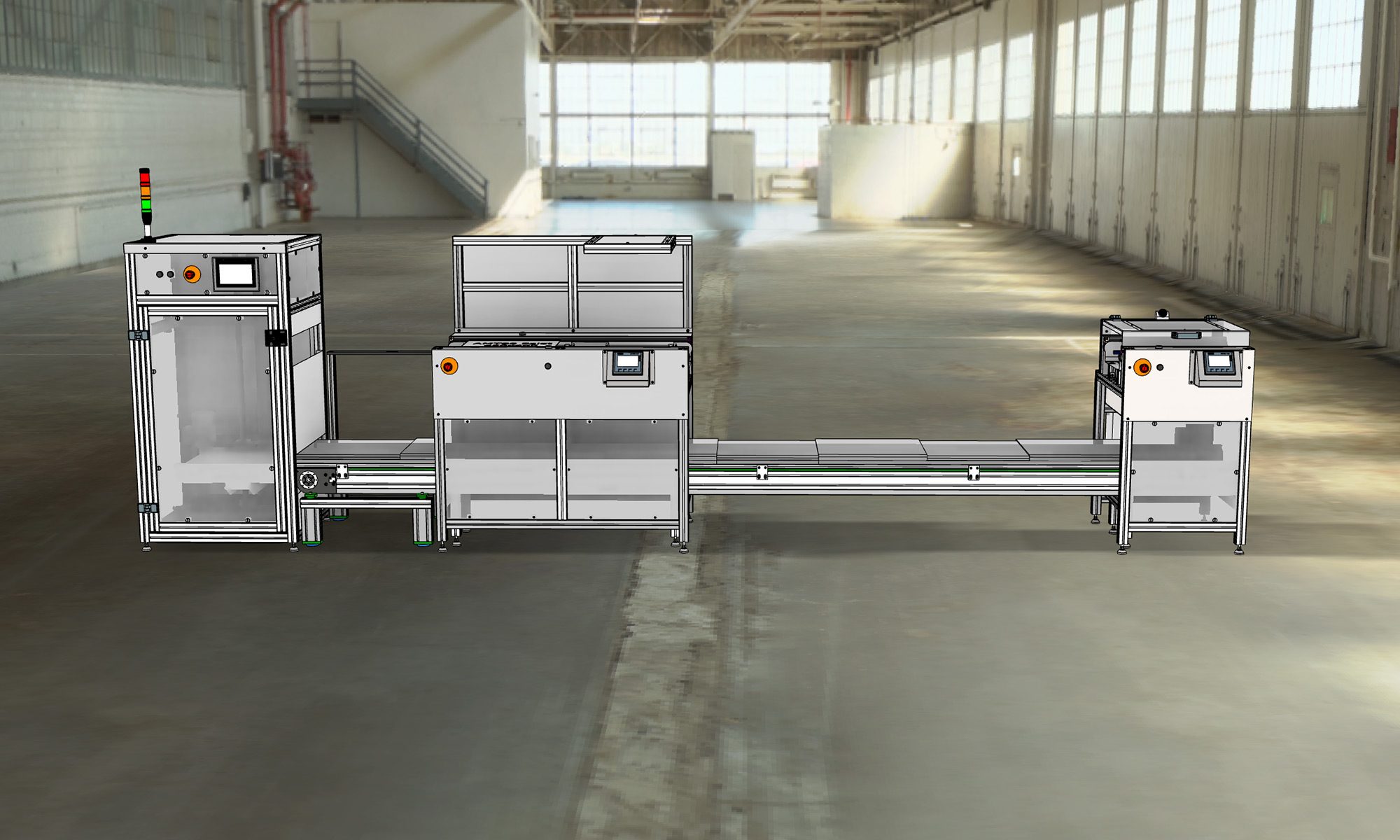

XL6500 is an SMT X-ray inspection machine with inline microfocusing for electronic components. This automatic X-ray inspection machine can be connected directly to the SMT production line or can be used offline with load and unload conveyors. Fully automatic judgment and inspection are performed for the characteristic area of the designated PCB or device.

Advantages XL6500 Inline X-ray Inspection Machine

- Automatic underline inspection of LED chip packaging.

- Fully automated online inspection of IGBT chips.

- 130KV 5um closed X-ray tube, long life, maintenance free.

- Use a high-resolution flat-screen digital detector with 2.3 million pixels.

- Fully automated online inspection of IC/BGA semiconductor devices, SMT and PTU packages, sensors and other areas.

- Fully automated online inspection of large PCB boards and PCBA solder joints.

- The simple operation of the template setting guaranteed reliable operation.

- Navigate through color images.

- Supports image stitching (optional).

- 3D upgradeable module (industrial TC) (optional).

Specification of the ZM XL6500 online X-ray inspection machine

X-ray tube source specification

| Type | Sealed Micro-Focus X-Ray Tube |

| Voltage | 90 KV (130KV optional) |

| Operating Voltage Range | 40-90KV/130KV |

| Operating Current Range | 10-200 μA/300μA |

| Max Output Power | 8 W/39W |

| Micro Focus Spot Size | 5-15μm |

Flat screen detector specifications

| Tip | TFT Industrial Dynamic FPD |

| Pixel Matrix | 1536×1536 |

| Field of vision | 130mm×130mm |

| Resolution | 5.8Lp/mm |

| Executive (1×1) | 20fps |

| A/D conversion bit | 16 bits |

| Dimensions | L1600mm×L1700mm×H2100mm |

| Input power | 220V 10A/110V 15A 50-60HZ |

| Maximum sample size | 510mm×650mm |

| Industrial PC control system | WIN7/ WIN10 64-bit |

| Net weight approx. | 2350 kg |

| Radiation | <1μSv/h |