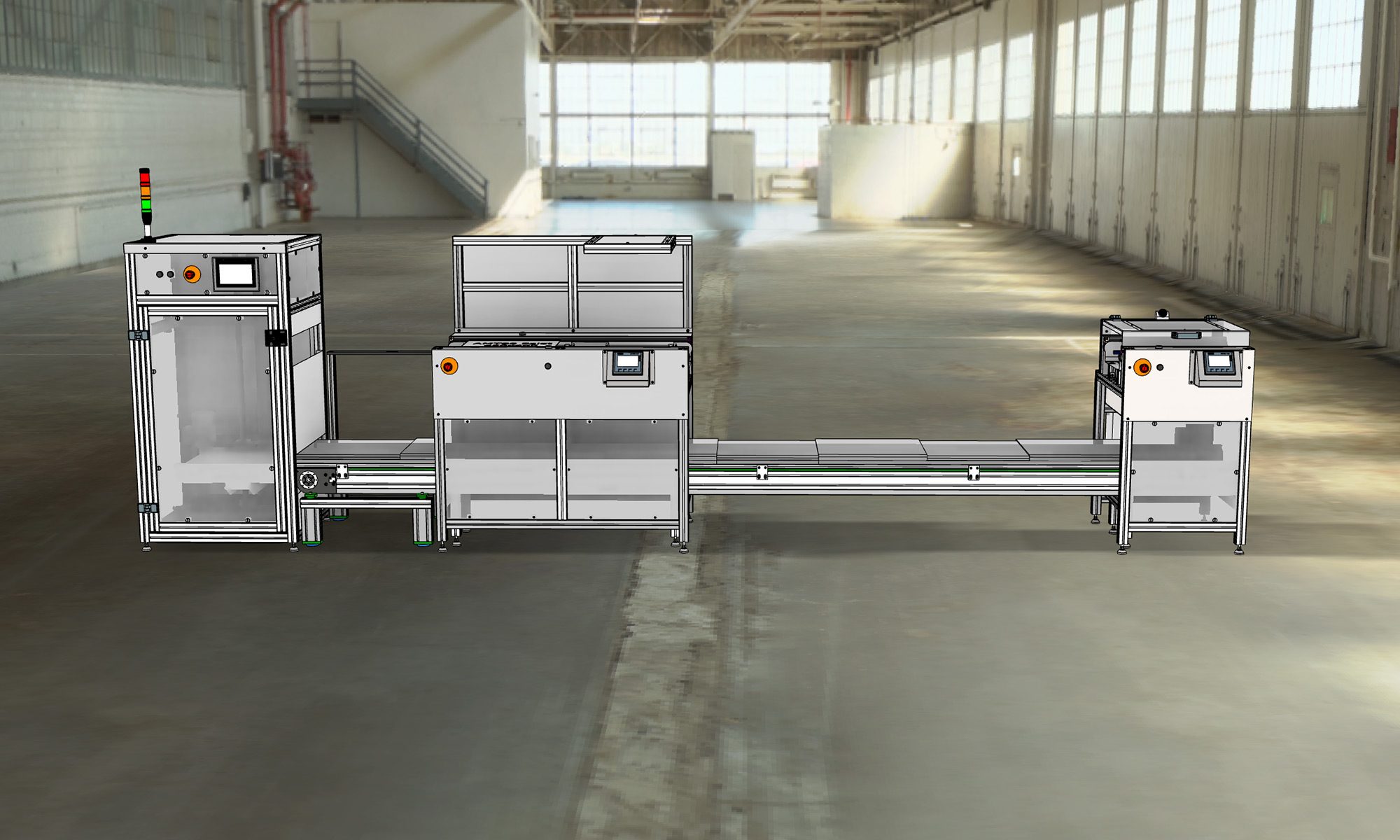

The ZM-R730A large-plate BGA rework station is a kind of semi-automatic soldering machine. The machine features stable temperature control, a large HD touch screen, HD optical alignment and intelligent control, as well as removable infrared temperature zone and other advantages. As one of the most reputed and professional BGA Rework Station suppliers, Zhuomao promises to produce the best good quality products.

Functions of the R730A semi-automatic big board soldering machine

- Stable temperature control

Three independently controlled temperature zones, heated by convection hot air, the height of the lower temperature zone is adjustable, the upper temperature zone has a built-in vacuum suction nozzle for chip absorption, with negative pressure monitoring and pressure protection device. - Large HD touch screen

Large HD touch screen operation with a variety of operation modes, real-time display and edit the temperature curve, each temperature curve group can be set to 8 segments, can store 100 groups of temperature curves, can automatically analyze the curve, read by touch screen control. - Removable infrared temperature zone

The IR preheat zone is heated by a carbon fiber infrared tube and protected by a high-temperature resistant microcrystalline panel. It can move left and right to facilitate maintenance of large and irregular PCBA. - HD optical alignment and intelligent control

Equipped with automatic feeding device using Panasonic PLC and high precision temperature control mode, high precision K-type thermocouple, selective reflow soldering process with multi-loop dynamic PID control, the accuracy can reach ± 1 ℃. Over-temperature protection alarm function, software encryption and secure function.

Specification of the R730A semi-automatic large-plate soldering machine

| Food | AC380V±10% 50/60HZ |

| Power | 7,75 KW (max.), top heater (1,45 KW) bottom heater (1,2 KW), preheater IR (4,8 KW), others (0,3 KW) |

| PCB size | 632*520mm (Max); 66mm (Min) |

| BGA chip size | 8080mm (Max); 33mm (Min) |

| IR heater size | 570*435mm |

| Temperature sensor | 5 pcs |

| Operating method | 10″ HD touch panel (1080P 16:9) |

| Control system | Panasonic PLC + temperature control module |

| Display system | 15″ HD industrial screen (1080P 16:9) |

| Alignment system | 2 million pixel HD digital imaging system, automatic optical zoom with laser red dot indicator |

| Vacuum adsorption | automated |

| Alignment accuracy | ±0.01 mm |

| Temperature control | Thermocouple Type K Control closed-loop thermocouple accurate to ±1℃ |

| Power supply device | from |

| Location | V-groove with universal fixing |

| Dimensions | L1000L835*H960mm |

| Weight | 130.5 kg |