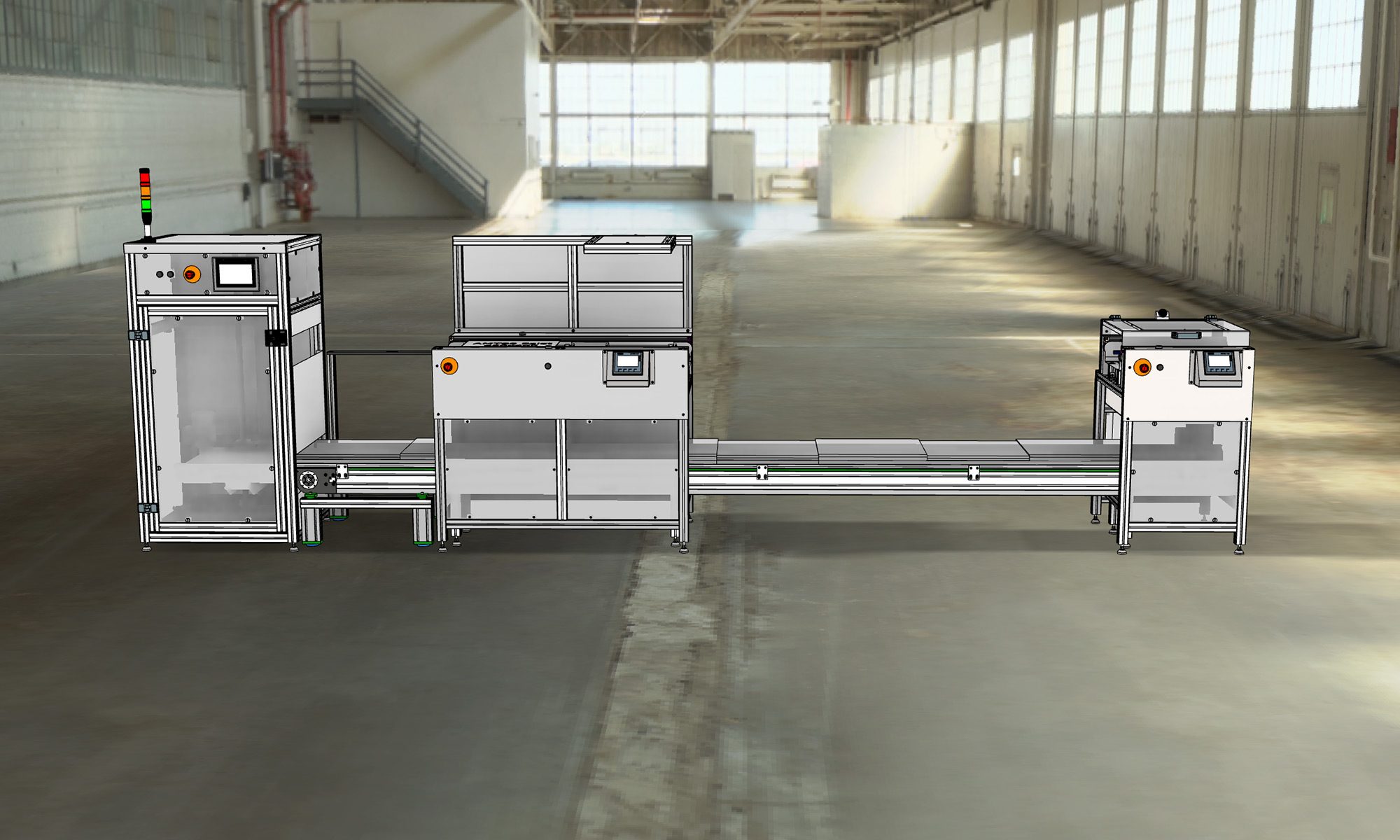

The XB7300 provides a fully automated inspection process for multi-layered winding batteries. It meticulously analyzes critical components of winding and energy storage batteries, such as positive and negative electrode plate alignment, large surface folds and pull pins, guaranteeing all-round quality control.

Features XB7300-Digital Battery Inspection

- Top X-ray technology

The XB7300 utilizes the renowned Hamamatsu X-ray tube, a global leader in precision X-ray technology. This ensures accurate and detailed inspections of winding coils, guaranteeing high quality performance. - Innovative algorithm integration

Featuring proprietary SeamarkZM algorithm software, the XB7300 incorporates state-of-the-art algorithms. These algorithms improve the machine's ability to analyze intricate details in batteries, leading to accurate and reliable quality assessments. - Expert Support

SeamarkZM offers unmatched customer support with a specialized team of professionals. Their knowledgeable research and development (R&D) experts and after-sales service team provide fast and efficient solutions. This dedication ensures trouble-free operation and reliability for companies that rely on the XB7300 digital battery inspection machine.

XB7300 digital battery inspection specifications

| Equipment size | 8500mm x 3200mm x 2800mm |

| Rhythm | ≥30 PPM and more (2 corners or 4 corners) |

| Excellence rate | ≥99,5% |

| Equipment failure rate (DT) | ≤2% |

| Overkill Rate | ≤1% |

| Underkill Rate | ≤0% |

| Accuracy of the blood pressure test | ±(0,0035﹪rdg.+0,0005﹪fs) |

| Accuracy of the internal resistance test | ±(0.5﹪rdg.+0.10mΩ) Radiation safety standard: ≤1μSV/h |

| Accuracy of repeated testing | ≤40um (standard part measurement) |

| Test content | IV, OCV, thickness, size, angle position, elevation (positive and negative polarity difference) |

| X-ray tube voltage: | 40-90KV/40-130KV |

| Current | 10 - 200 uA / 10 - 300 uA |

| Receiver | Flat screen detector |

| Measuring thickness | Measurement accuracy ± 0.02 mm |

| Time to take | ≥ 0,7 S |

| Input material | Stacking, loading and unloading tray method |

| Model changeover time | Model changeover time for old varieties is ≤2 person-hours; model changeover time for new varieties is ≤4 person-hours. |

| Mini compatible range: | Length: 40~160mm; Width: 35~120mm; Thickness: 5~15mm Normal: Length: 40~160mm; Width: 35~120mm; Thickness: 5~15mm (or customized) |